From Yuma to Suffield and beyond

Following the conclusion of extended field test, Harmony joins forces to win the Pop-Up City Contest finale and garners international recognition at the Global Prize in Desalination

Circular City, a consortium led by Innocorps Research Corporation, was recently announced as winner of the Pop-Up City Contest ($2M CAD grand prize). The week-long demonstration of our mobile water, waste, and power management system took place at CFB Suffield in Alberta, Canada this August. For Innocorps, this was the long-anticipated culmination of a four-phase contest and four-year journey. For Harmony, this was a timely opportunity to field test our batch reverse osmosis (RO) process in a second application: wastewater re-use. Read on for an in-depth account of how this successful partnership came to be.

For more about the Pop-Up City Contest, see the following:

Table of contents

Extended field testing (Yuma, AZ) ↑

Harmony had proven the effectiveness of its batch RO process during the week-long More Water Less Concentrate (MWLC) challenge in August 2022. The Bureau of Reclamation announced the Olin-Harmony-MIT team as winners of the $150k grand prize, with those funds used to support Emily Tow's research on fouling and Harmony's continued development of batch RO.

The next step was to establish batch RO's long-term reliability through extended testing at the Water Quality Improvement Center. Knowing that customers would like to see as much operating data as possible, we commenced extended piloting in September. The first month was eventful as we pushed el Titan past its breaking point. Leading causes of downtime included leaking hoses and a broken pump diaphragm. We bought stronger hoses and added a strainer to protect the diaphragm pump, and our uptime improved.

el Titan was monitored, operated, and serviced by staff at the Water Quality Improvement Center. The Bureau of Reclamation allowed us to use the facility free of charge. This work was support financially by a Massachusetts Clean Energy Center (MassCEC) Catalyst Grant.

Harmony is working to identify the limits of batch RO's scaling resistance. During the MWLC challenge, we had dosed the batch RO feed with sulfuric acid to discourage formation of gypsum scale. After a successful week with no apparent scaling, we discontinued the sulfuric acid addition and relied entirely on the antiscalants already present in the Yuma Desalting Plant (YDP) feed. This would be a real test of batch RO's ability to recover more water from a scaling-prone feed with minimal chemical addition.

The brine coming out of the batch RO system was clearly supersaturated, with crystals dropping out of solution in the reject tank. Lab testing of the reject confirmed that gypsum was supersaturated (SI = 0.65). After the pump failure, we brought the system back online in November and saw permeate quality decline steeply. We feared that scaling was the cause. However, a membrane autopsy performed by Genesys Technologes (San Diego, CA) found minimal signs of inorganic matter on the membrane surface. Rather, residual chlorine from the YDP feed had reacted with the polymer membrane and impaired its ability to reject salt.

Fortunately, there was a simple remedy for membrane chlorination. We started dosing sodium metabisulfite (SMBS) to react with the free chlorine and protect the membranes. Operators were instructed to monitor oxidation reduction potential (ORP) levels and adjust dosing accordingly. So long as we kept dosing SMBS, permeate quality remained within spec. By the conclusion of testing in July 2023, el Titan had produced 306,806 gallons of potable water at an overall water recovery rate of 80% with the longest streak of continuous operation clocking in at 528 hours.

IDA World Congress (Sydney, AUS) ↑

In October, Harmony founder Quantum Wei flew to Sydney, Australia for the 2022 International Desalination Association World Congress. This biennial gathering brings together researchers and practitioners of desalination and water re-use from all around the world to learn from each other and to connect with potential partners, suppliers, and customers.

Quantum gave a presentation to share lessons learned from initial field testing and promising applications where batch RO could solve problems. He made the case for using batch RO in remote locations such as mines due to its robust design and ability to integrate with renewables. His talk concluded with an open invitation for partners to host a pilot test of the batch RO process.

Soon afterwards, Innocorps CEO Aarya Shahsavar approached Quantum with a proposal. Could batch RO be used to increase the water recovery of a mobile wastewater re-use system? Innocorps was leading the Circular City team, finalists in the Department of National Defence's Innovation for Defence Excellence and Security (IDEaS) Pop Up City Contest. The goal would be to minimize liquid waste while maintaining low energy usage. Being a mobile application, it would be critical to avoid membrane scaling and ideally with no consumables (i.e. antiscalants). However, there would be minimal knowledge of the precise water composition prior to the demonstration. Finally, the setting would be a contest, so a non-critical setting.

It seemed perfect.

Partnership with Innocorps (Yuma, AZ and Saskatoon, SK) ↑

After returning home Harmony and Innocorps had some more discussions before quickly organizing a couple of trips.

In January, Quantum flew to Yuma for a minor rework of the prototype. The improvement would improve water recovery and reduce downtime. Aarya also flew down to Yuma to check out el Titan. He got to see how the process worked first hand and also get his hands dirty, helping out with electronics, piping, and bladder installation.

In February, Quantum flew to Saskatoon to visit Innocorps headquarters and meet the whole team. He and Aarya visited one of the Innocorps pilot sites at a small farm just outside of the city. Not being hooked up to the municipal water supply, this farm was reliant on well-water. However, rust was a big issue and ruined the residents' laundry. With the help of Innocorps small water treatment boxes, iron and other contaminants were removed. Rust no more!

Back at Innocorps, Quantum got a tour of the Innocorps facility. There was discussion on how batch RO would be integrated into the Circular City SEACAN-3 and brainstorming on how to cheaply make a recirculation pump. In the evenings, Aarya took Quantum around to sample Saskatoon's nightlife, including some incredibly spicy wings and some hit-or-miss stand-up.

Quantum flew back to Boston. After some more exchanges, Innocorps and Harmony signed a formal agreement on May 19th to work together with the goal of winning the Pop-Up City Contest.

Pilot prep at Artisans Asylum (Allston, MA) ↑

Once the partnership agreement had been signed and parameters were set, there was only three months to be ready for the Pop Up City (PUC) Contest finale, scheduled to take place in late August. Preparations were further complicated by the decision to upgrade the el Titan prototype still undergoing testing in Yuma, rather than building a new system from scratch.

Harmony hired Alondra Hernandez and Eliana Razzino as engineering interns for the summer, supported by the MassCEC Clean Energy Internship program. Eliana was tasked with improving the design and manufacturing process of the batch bladder. Alondra assisted with many aspects of pilot delivery and would prove indispensable in the field.

Coordination between Harmony and Innocorps was required on several important matters. el Titan would ultimately integrate into the Circular City wastewater treatment train, so the skid needed to fit through the doors of the shipping container and alongside existing equipment. Innocorps would also be developing a new control box for el Titan which would be shipped down to Yuma for shakedown testing prior to crossing the border for the contest.

Harmony hired a mechanical engineering consultant based in India to put together a computer-aided design (CAD) assembly of the new system. This confirmed that the redesigned skid would fit into the available footprint and contributed to a bill of materials (BOM) for both the new frame and the reconfigured assembly of pipes & fittings.

There were no particular constraints on system footprint for the MWLC challenge, so el Titan v1 was mounted onto two wooden pallets. For the PUC Contest, pressure vessels would be mounted vertically to save space and facilitate installation of the bladder. The frame for el Titan v2 would be constructed anew and was made from aluminum extrusion (80/20) at the machine and metal shops in Artisans Asylum (Allston, MA). Time in Yuma would be limited, so Alondra and Quantum practiced assembly of the frame several times at Artisans before shipping the disassembled (but carefully labeled) frame out to Arizona ahead of their flight.

There was no way to pre-assemble the hydraulics, so new pipes & fittings were ordered directly to the Water Quality Improvement Center.

el Titan brine concentrator, v2.0 (Yuma, AZ) ↑

On the evening of June 26, Quantum and Alondra flew from Boston to Phoenix before driving three hours through the midnight desert to Yuma. The initial plan was to upgrade el Titan within five days, leaving fourteen days for shakedown testing. A day was already lost as the two had missed their original flight. The pressure -- and the heat -- was on.

Before commencing the rework in earnest, there was one last opportunity to run el Titan v1 for Alondra's benefit and to test a new rubber bladder Eliana had made. This effort was stymied by a plastic support rod which had fractured after 11 months of service. We planned to replace the rod with PEX and retired for the day.

Quantum spent the better part of Wednesday disassembling el Titan while Alondra assembled the new frame. Installation of the main components (tanks, pressure vessels, pumps, and some fittings) progressed slowly but steadily over the next two days. By Friday night, el Titan's new form had become apparent.

Quantum completed the low-pressure piping on Saturday. By Sunday, he realized some high-pressure fittings were missing. Delivery would not be possible until Wednesday due to July 4th, so on Sunday night he made the four hour drive to Los Angeles. Monday morning, he picked up the required components from the McMaster-Carr warehouse and drove back to Yuma to continue assembly. Assembly of the high-pressure side was substantially complete by Tuesday afternoon. Just in time for fireworks -- and for the arrival of reinforcements (!!) from Canada.

Aarya Shahsavar and William Davis from Innocorps had arrived with a critical component: the brains of the batch RO system. For the 10 month long trial, el Titan had been running off of a National Instruments DAQ and a Windows laptop running MATLAB. It's what we were able to put together for the MWLC challenge and had worked well enough for extended testing, but was clearly not a viable solution moving forward. Innocorps had developed their own control boxes for small water treatment systems and agreed to build, program, and deliver the control box for the Pop-Up City contest. Aarya also had some critical electrical components which were needed to hook-up the new box to power at the WQIC.

Over the next several days we worked hard to get el Titan up and running before our Canadian teammates were scheduled to fly back up. Late Thursday night, we got water into the system and were able to open and close valves with the new control box. This was not nearly as far as we'd hoped to be, but it would be enough. Quantum would stay behind and continue setting things up. The box could connect to a cellular hotspot and William would push software updates remotely from Saskatoon as needed. After a much needed break in San Francisco, Quantum eventually got the system running continuously before flying back to Boston July 18th.

Throughout this trip the daily high was typically upwards of 110 degrees. Fortunately we were working indoors and the WQIC has pretty decent swamp coolers. However, the heat took a toll on all of us, particularly towards the end of the trip. In one memorable moment, the three of us were clearly impaired in our decision-making and feeling sluggish. But it felt so close to the finish, we were tempted to push on and wrap things up. Instead we took a break for dinner, some treats, and a visit to the border fence. We returned to a cooler WQIC after sunset, refreshed and hydrated. In retrospect, definitely a good decision to take a pause and avoid a costly setback.

Quantum returned to Yuma July 24th and 25th to pack the system up and ship it to Canada. Just over a year of testing at the Water Quality Improvement Center was complete.

Pop-Up City Contest finale (Medicine Hat and Suffield, AB) ↑

After a couple weeks back in Boston for final preparations, Quantum and Alondra flew to Calgary on August 7 and drove three hours east to Medicine Hat. "The Hat" would be our home base for the Pop-Up City Contest which would take place at an airstrip at CFB Suffield, an army base not too far away.

Set-up

On our first morning, we met at the designated hotel for check-in and breakfast before driving in a caravan (obeying the speed limit) to CFB Suffield. During the two weeks allotted for set-up of the camp, we were only allowed on-base between 08:00 and 17:00 hours. No base access on the weekends. After we checked in to the base, we drove to an airstrip which had been transformed in to a Pop-Up City of its own. For just over three weeks, it would host the three finalist teams and all of the support staff needed to run the whole production. After a brief camp orientation, we headed to our section of the airstrip and got to work.

Unfortunately, el Titan wasn't there yet. There had been a three-day delay in the crates getting picked up from the WQIC at the end of July. Our two crates slowly made their way up towards the border, but were stuck at customs due to a mismatch in paperwork. On that front, all we could do was make the right phone calls, send some emails, and wait. In the meantime, we made ourselves useful by helping the Innocorps team with camp set-up.

There was much to do with lots of pieces to put together. The idea behind this contest was to provide utilities for a 150 person relocatable temporary camp (RTC) in as efficient as manner as possible. This meant providing enough potable (120 L/day) and hot water (30/L day at >60° C) to live comfortably, processing solid and liquid waste, and all the requisite energy to boot. Innocorps was the system integrator and had also developed the wastewater recycling system. By recycling wastewater, we'd accomplish two goals at once: reduce liquid waste and produce potable water. EcoGrowth, a Calgary company, was in charge of processing solid waste with their dehydrators, shredders, and gasifiers. We can thank the gasifier exhaust for our hot water supply, the perfect temperature for a shower (or a hot tub). For energy, Circular City had opted for dual generators as the primary supply with a small array of solar panels and batteries as a supplement.

For the next several days, we contributed where we could to setting up the camp. Innocorps had a team of seven: Aarya, William, Alexander Chan, Adam Clark, Dawson James, Brent Wirachowsky, and Ryan Wynquist. We set up modems so that the wastewater treatment containers could be monitored and controlled from the control container. We organized hoses and wires so nobody would trip walking around the camp. We unrolled onion tanks to hold the potable water before discharging through a flowmeter to tally our water production during the contest.

On Friday, we drove back to Calgary to pick up some supplies. Alondra would explore Calgary and Banff over the weekend while Quantum flew to Montreal for a friend's engagement party. Late Sunday night, the two drove back to Medicine Hat ready to get back to work. Just five days of prep left before the contest would kick off on Saturday morning.

Finally around mid-day on Monday el Titan arrived, having been released from customs and signed over to a new freight provider, Crane Worldwide. We quickly got to work putting el Titan back together. It had never run with the rest of the wastewater treatment train, and we certainly wanted to get some operating hours in before the contest kicked off. Fortunately, we didn't lose out on much shakedown testing because there wouldn't be any water to treat until Wednesday.

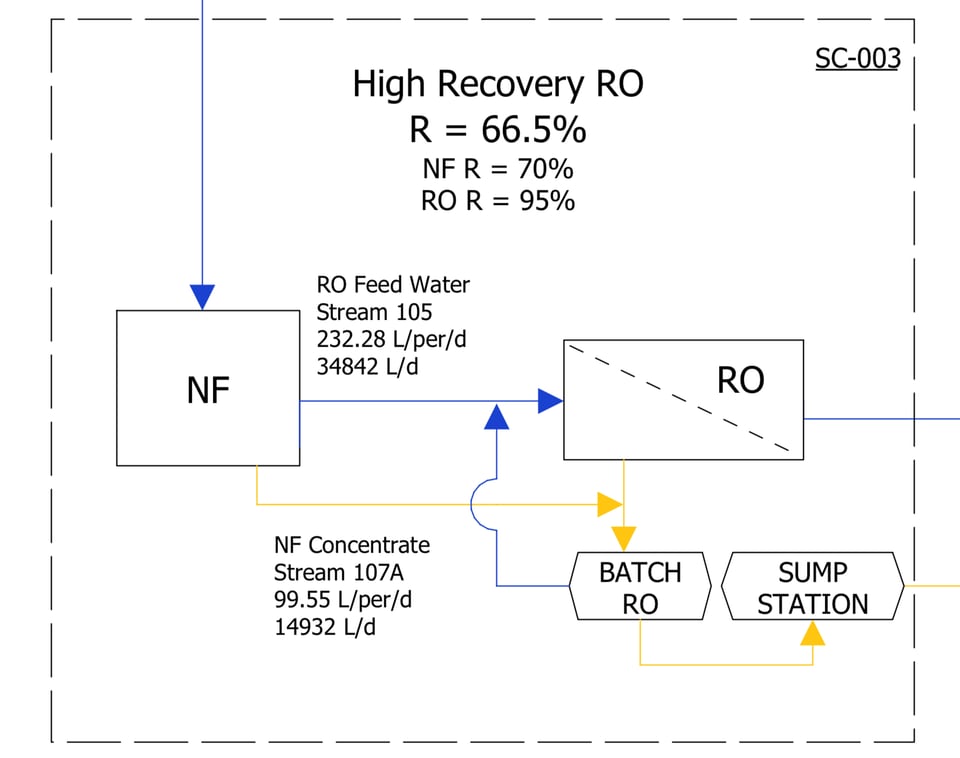

el Titan had been partially disassembled for shipment. Reassembly took about a day and a half. We broke one of the solenoid valves (a critical component) during this process, but fortunately had a back-up on hand. On Wednesday, we wet-tested el Titan just outside the container. Then it was off to Calgary so that Alondra could fly home -- it was the end of her summer internship. On Thursday it took a team of four (Ryan, Brent, Dawson, and Quantum) the morning to place el Titan into the shipping container alongside the nanofiltration and RO systems. Once integration was complete, we had day or two to shakedown the full wastewater treatment train before the competition would kick off at 1100 hours on Saturday. Quantum would spend a lot of time in SEACAN 3 troubleshooting el Titan with regular trips to the control container to ask William to modify the control code.

Although Suffield is the sunniest city in Canada, there were several days of clouds and storms during the set-up period. This did not bode well for the two other teams who relied primarily on large solar arrays and a tall pop-up wind turbine, which greeted us each morning as we drove into camp. We had high hopes going into the contest but still had to execute.

The contest

Once the contest began on Saturday, teams would be allowed on-site 24/7. Aarya, Alex, Ryan, William, and Quantum took the day shift while Brent, Dawson, and Adam were on duty overnight. So began a whirlwind seven days with a predictable and packed schedule:

- 0600 wake up for breakfast at the hotel

- 0730 arrive at Pop-Up City for a walk-through with the night shift

- 0800 official start of our twelve hour shift

- 1930 walk-through with the night shift

- 2000 drive back for dinner and discussion

- ???? sleep

Day 1 - Saturday

With a fresh set of membranes installed, we were off to a good start as the contest officially kicked off shortly after 11:00.

Batch RO pressures had been relatively low compared to Yuma during set-up and the first couple hours of the contest, as expected since the feed salinity was about half as high. However, by the end of our shift on Saturday the feed pressures and pressure drops across the membrane channel had both risen to abnormally high levels.

Could we have scaled the membranes that rapidly? This seemed unlikely, given the feed wasn't thought to be nearly as scaling-prone as in Yuma. However, the system was still producing potable water so we continued to let it run. This system still wasn't quite dialed in, so Quantum sent the night shift a bunch of notes before dinnertime.

Over the course of researching, Quantum read the following passage from the Dow Filmtec Manual:

g. Precipitated Antiscalants

When polymeric organic antiscalants come into contact with multivalent cations like aluminium, or with residual cationic polymeric flocculants, they will form gum-like precipitation which can heavily foul the lead elements. Cleaning will be difficult; repeated application of an alkaline EDTA solution may help.

Could this be the cause? Antiscalants were being dosed into both the nanofiltration and RO polishing steps. Each of these were running at extremely high recoveries (>90%), so antiscalant concentrations in their reject (i.e. the batch RO feed) would be at least 10x higher.

Day 2

The night crew had shut down el Titan overnight. Quantum spent much of Day 2 in SEACAN 3 babysitting the system. In addition to the elevated pressures, the Variable Frequency Drive (VFD) on the pressurizing pump kept tripping and needed to be manually reset. Perhaps the elevated pressures and the VFD tripping were related? Quantum combed through the VFD manual in search of a parameter which might be adjusted to stop the VFD from tripping so often.

Despite issues with el Titan, the rest of the mobile direct potable reuse (DPR) system was operating quite well and Circular City was easily hitting the clean water production targets. Taking a stroll by the EcoGrowth containers was quite pleasant as they had been given leftover cookies to dispose of.

During the walkthrough that evening, Dawson noticed that an in-line filter on the high pressure side of el Titan looked corroded. Indeed, the filter had been poorly selected and was not constructed of stainless steel. Maybe this was the cause of the elevated pressures! Dawson offered to remove the filter overnight, and perhaps this would solve a problem.

Day 3

Day 3 started out quite similarly to Day 2. el Titan was producing clean water in fits and starts. Pressure were still abnormally high and the VFD continued to trip. Just after lunchtime, Aarya arrived with additional supplies, including an ammeter. A quick check of the individual line currents on the VFD confirmed that the motor had gone bad. So much for an easy software fix. A motor replacement would be required.

Unfortunately, the new frame design had prioritized a compact footprint over serviceability. The pressurizing pump and motor were not easily accessible. el Titan was shut down and drained, and the frame pushed slightly aside so that the piping in the back could be disassembled. It took both Alex and Quantum to extract the pump-motor assembly from a cage of aluminum extrusion. Quantum then replaced the bad motor with a back-up motor. The VFD needed to be rewired, the pump-motor assembly inserted back into its cage, and the piping reassembled. Before we knew it, the day shift was almost over. It was a mad scramble as Alex and Quantum strove to get el Titan back up and running before the night shift.

Slightly past 20:00 el Titan had a new motor installed and was running, but not holding any pressure. Quantum had decided to take out the old membranes and put in new ones. The cause of the elevated pressures had not yet been identified, and there were only two pairs of fresh membranes left. In an attempt to diagnose the problem in steps, Qunatum had only installed one membrane element. However, without plugging the unused permeate port feedwater was intruding into the permeate port. Whoops.

Alex, Will, Ryan, and Quantum had dinner at The Keg, a Canadian steakhouse which was conveniently located right next to the hotel. Afterwards, Quantum drove back to CFB Suffield to install the second membrane with some help from Adam. For a glorious five hours or so, el Titan produced clean water before being shut down in the middle of the night shift due to a leak.

Day 4

At least one problem had been solved during the Day 3 re-work. With a new motor installed, the VFD was no longer tripping. However, during Day 4 the batch RO pressures rose to basically double the levels which had been seen the evening before. The high pressure limit was being hit consistently despite the feed salinity being much lower than in Yuma. Clearly, something was still wrong and the membranes were somehow getting clogged.

The evening shift took over following a heated discussion between Quantum and Adam. Quantum's prevailing theory was that the concentrated antiscalants from the NF systems were the cause for the membrane issues. He advocated that scaling dosages be turned down or even stopped in a coordinated manner. In Adam's view, the antiscalants were necessary to guarantee the uptime of these critical water-producing systems. It would be tough to reach an agreement without positive identification of the foulant.

Aarya, Ryan, and Quantum got together at the hotel after dinner to prepare for Demo Day presentation. Then, an important update from the evening shift. Dawson had noticed a slick of oil in one of el Titan's overflow tanks. After some investigation, it became clear that there was oil in the batch RO feed. Normally, membranes and oil do not mix at all. Clearly, this would cause the membranes to foul and hit the elevated pressures we had been seeing all week.

But why would there be oil in the feed? After some thought, Quantum realized what had happened.

Flashback to Yuma (July 25)

During his second trip to Yuma in July, Quantum had two days to pack up el Titan and its associated parts before flying back to Boston. There was much to do, like draining oil from the pumps prior to shipment. It was already a rush to pack up in time for freight pick-up, and he was definitely a worn out from many successive days of working in the heat.

While draining oil from the high-pressure pump, Quantum broke the plastic oil filler cap. Quick to action, he grabbed a drill to extract the cap from the crankcase. This solved the immediate problem and was able to drain oil from the pump before packing it away. However, in the process of solving one problem he had potentially created another. He had drilled away a bit of the crankcase material. There were potentially metal shavings in the crankcase which might cause problems later on down the road. He made a mental note and moved on to more urgent matters.

Quantum brought the high-pressure pump back to Boston and gave it a cursory cleaning with some compressed air at Artisans Asylum. In hindsight, this was not enough. It seemed clear that somehow the metal shavings were causing oil to leak from the high-pressure pump and into the batch RO feed.

Not a great realization, but at least now we knew what causing the membranes to clog up.

Day 5 - Demo Day

Unfortunately, we would have to wait to address the oil leak, because Day 5 was Demo Day. Scores of visitors from the military, industry, and government were scheduled to hear presentations from the three finalist teams before walking through on guided tours of each Pop Up City.

Aarya gave the presentation for Circular City, opening with a graphic from 2001: A Space Odyssey. He quickly worked up to the big reveal, holding up a bottle of pristine water: recycled wastewater from our site. He drank a couple big gulps in front of the audience. Of course, lab results from Southern Alberta Institute of Technology (SAIT) had confirmed that the water's heavy metals levels adhered to California direct potable reuse standards. Aarya invited the visitors to see our system and to drink the water for themselves.

The rest of the morning and early afternoon were a whirlwind as we shepherded visitors around the various containers that comprised our camp. Although Brent had been working evening shifts the whole week, he stayed up to join the day shift in giving tours of the camp. We got a lot of good feedback from the visitors on what they liked about our camp (consistent interfaces, easy to set-up and takedown) and what could be improved (hardened against environmental surges, able to operate as 'dumb' systems).

The team was primed for the show and tell and wanted to put our best foot forward. Some of these visitors were judges who would be awarding contest points. Others were prospective users or customers. We settled into a rhythm of passing visitors off between different portions of the camp. Before we knew it, visit day was nearly over. Everyone gathered under the big tent for a debrief, and then the visitors drove off of the base.

Once the visitors had left for the day, Quantum and Will immediately got to work on fixing the issues with the oil pump. The pump was removed from the motor and then carefully taken apart, with plenty of pictures taken for the re-assembly. A careful inspection by both Quantum and Alex revealed no obvious damage to the O-rings. However, there were definitely metal shavings in the crankcase. With healthy doses of pump oil, the shavings were meticulously removed from the crankcase. Reassembly of the pump was the next task, guided by photos and CAT's helpful video tutorials. This went off mostly without a hitch, although one step had to be repeated because the head had been assembled backwards and would not fit into the piping.

The evening shift arrived just as we were hooking the pump back up to el Titan. When loading new oil into the pump, Dawson pointed out that we had overfilled the crankcase the first time. In any case, it seemed that the metal shavings had been able to sneak past the O-rings and carried some oil along with them and fouled the membranes. We could only hope that we had removed all of the shavings and that there was no damage to the O-rings which would allow additional oil into the feed. We got the system up and running again. The plan was to leave the system running overnight with the fouled membranes to flush out as much of the residual oil as possible.

During the evening shift, Adam noticed that the batch RO permeate exceeded spec (1200 uS/cm) and shut it down.

Day 6

First thing first: Quantum and Ryan put in the last pair of fresh membranes (a test set from Aquamembranes) into el Titan. By this point, the two had developed a nice process and got the membranes in and the system up and running rather quickly. With a fresh set of membranes and the oil leak seemingly repaired, el Titan operated fairly smoothly. With less to do, Will and Quantum took some time to tour the other camps.

After lunch, there was only one item left on the agenda: a planned shutdown. All of the camps would shut their systems down entirely for a period of at least ten minutes. Then we would be allowed to restart the camp. Each team would be timed on how long it took to resume full functionality, and points would be awarded for rapid startups.

For a moment, all was quiet as the generators and motors stopped spinning. The day shift took advantage of the downtime to lay for a rest on the onion tanks. Filled with water to varying degrees, the tanks served as makeshift water beds and felt cool to the touch. But before long, it was time to get ready for the restart. We each headed towards our respective containers and got ready to flip the switches. Once we received the go signal, Aarya got the generators going. In short order, we got the containers up and running. However, the judges would not stop their timer until we got a transfer pump by one of the MBRs going. For a hectic minute or so, the whole crew was standing by the pump as a few of us hurried to get it primed and operating. Finally, after a total startup time of about 5 minutes, the judges clicked their stopwatch and we could relax for the rest of the day.

Day 7

Friday was rather uneventful. In the morning we hit our freshwater production target for the week, nearly 24 hours ahead of schedule. We would not be awarded any additional points for producing more freshwater, but we could lose points for using more river water. Therefore, we decided to stop withdrawing river water. With less water coming into the system, our camp was running well below capacity. The potable re-use system ran in fits and starts as it ran out of wastewater to treat.

Without much to do, we relaxed in our zero gravity chairs and went on more tours of the other camps.

Day 8 - Saturday

Saturday morning was rather uneventful. Aarya and Quantum recorded ceremonial videos of each other drinking the recycled wastewater. During the last hour of the contest there was a scramble to push as much water as possible through the flowmeters as we got a head start on draining the onion tanks.

By the end of the contest, Circular City's mobile direct potable re-use had produced 179,108 L of potable water, exceeding the target by 13.7%.

Pack-out

There was no time to waste once the contest was over. Our team immediately got to work on packing out our camp. We would once again be kicked off the base by 5pm. The job was done, and people were eager to get back home. We made short work of it, as we disconnected hydraulic equipment and rolled back hoses. Solar panels were folded in and crated up. The onion tanks were drained, flipped open to dry, and rolled up into the storage container.

After a day and a half of hard work, we tossed the last of our rubbish into a dumpster and drove off into the proverbial sunset.

Global Prize in Desalination (Jeddah, SA) ↑

After a slow yet restful September back in Boston Quantum flew to Jeddah, Saudi Arabia to pitch at the Global Prize in Desalination. This was an opportunity to win not only $100k in cash but also a pilot program with the Saline Water Conversion Company. Quantum pitched the ability of batch RO to integrate well with renewables and reduce the size of seawater intake and brine outfall structures. Harmony was awarded by an international jury of desalination experts an Impact Medal for most promising technology to reduce chemicals and consumables. The award came with a nice trophy, $50k cash, and $75k in piloting support with SWCC.

The GPID and Innovation in Desalination conference brought together scores of desalination researchers and innovators. This confluence has already sprouted several seeds: a joint grant proposal with Arian Edalat at Active Membranes, a research collaboration with Hamid Samouei at Texas A&M, and a visit to Juanma Ortiz and Junkal Landabaru at IMDEAS Water.

In November, Circular City was announced as the winners of the Pop-Up City Contest. Victory!

Harmony plans to continue deploying batch RO systems around the world in a variety of applications. Stay tuned for more updates coming soon.

Want to join our crew? We're hiring!