Speedy Metals News - October 2025

An outstanding customer project, 10 years in the making.

CUSTOMER SPOTLIGHT

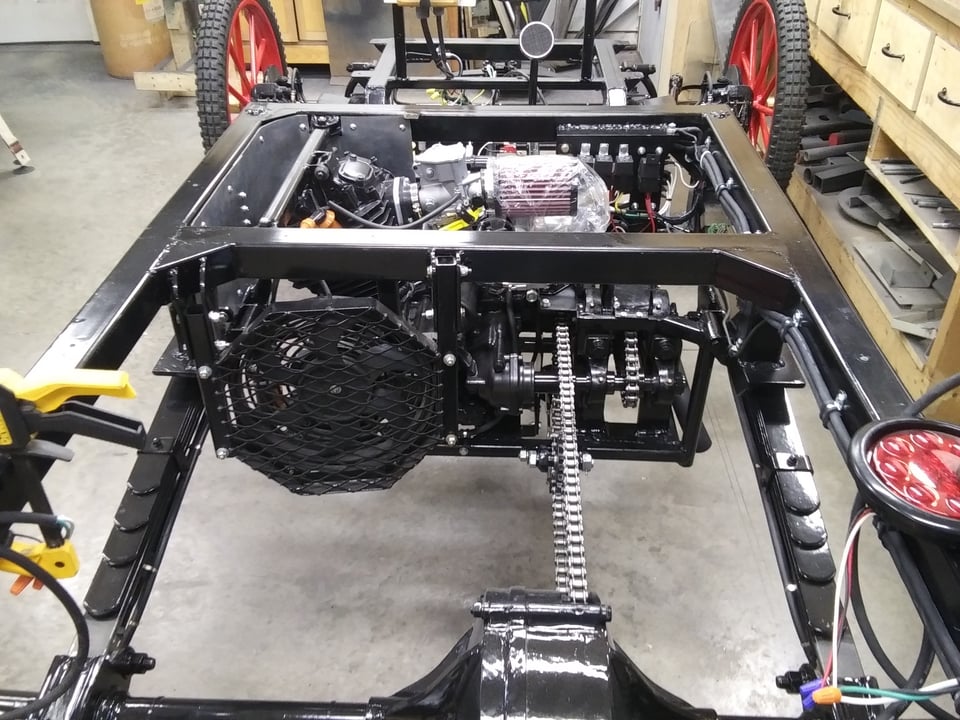

This month we’re featuring a 1904 Oldsmobile Light Delivery Horseless Carriage Replica by Bill Drumm.

He says:

“I started the CAD drawings in the fall of 2013 and finished the build in the summer of 2023. During the build it was called “Bill’s forever project”. This project has taught me patience. A lot of time was spent making templates, bucks to form parts, jigs, fixtures, tooling, CAD drawings, and G-code files to run on my homemade CNC router.

“This replica was blacksmithed together. By “Blacksmithed” I mean it was built by using my pass experience to determine how strong and what material to use in construction. I am not an engineer. I have done woodworking as a hobby in the past and have owned, raced, and maintained my own stock car. I have worked on race cars for 33 years total. Before I retired my job also required some fabrication and maintenance work. The Replica was designed and hand built by myself. Outside services used in the build were brass welding, aluminum welding, front spindle welding (1045 steel), spring fabrication, and forming of the rings and cones for the rear end construction.”

“The power for the carriage is a 1986 Honda FourTrax 250 ATV motor and transmission. This was chosen because it has electric start, automatic clutch, charging system, and a reverse gear.”

“The body is all wood including the hood and faux radiator (Wood frame covered in brass sheet).”

“Most of the metal used to construct the replica was from Appleton Speedy Metals. Some scrapyard aluminum and brass were also used. Steel used was DOM tubing, square tubing, rectangular tubing, round tubing, flat stock, round stock, and angle iron. Brass flat stock, brass round, brass sheet, aluminum flat, and aluminum sheet metal were also using in the construction of the replica.”

“My carriage is titled and licensed in Wisconsin so I will be able to drive it around town and on the back roads. Because of this I needed to have headlights, brake lights, and turn signals for safety. Surprisingly Wisconsin Statutes states that a replica vehicle has to meet the safety standards of the year it replicates (1904 is zero standards).”

“I decided to make may own lamp housings. I drew up some Neverout style lamps in CAD to fit the head and tail lights I decided to use. I used 4" Red LED Round Trailer Tail Lights and 4.5" Motorcycle Amber LED Fog / Passing Lights for the headlights.”

Want to see your work featured here? Send us an email at newsletter@speedymetals.com.

You can also check out other great customer projects on our blog or on our Facebook page.

WHAT YOU’RE SAYING

“I am becoming a minimally competent blacksmith; I am learning to become a functional machinist; and my knowledge of the tools and metallurgical properties is progressing. An indisputable fact is that everything you attempt to produce is no better than the place you start. With your company, and what you provide, the variables of my hobby are reduced - I start in the right place, I waste no time. Thank you Speedy Metals, and God Bless.”

-Michael

DID YOU KNOW...?

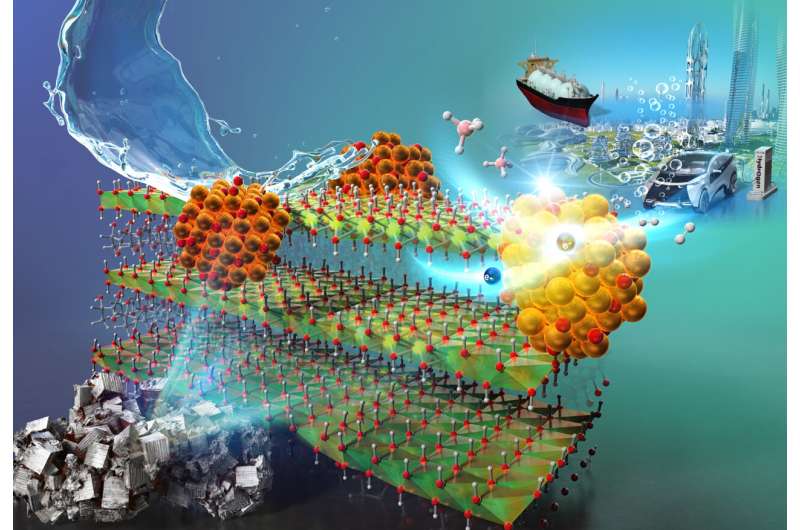

...that "Green Rust" may be the key to less expensive, more efficient hydrogen fuel cells?

Generating hydrogen for hydrogen fuel cells typically requires expensive catalysts, that use rare metals like platinum. But now, researchers have figured out that by stabilizing “green rust” (an unstable version of iron hydroxide) with copper chloride, they can produce hydrogen even more efficiently than with traditional catalysts.

According to the article, “The catalyst works at room temperature, is relatively easy to produce, and could integrate well with existing hydrogen systems.” So some day soon, cars and ships might be powered, in part, by rust.

Learn more in the full article here.